Step 5 roll the template into a cone shape overlapping the sheet metal by 1 2 inch then drill a few holes along the seam and seal it closed by placing rivets in the drilled holes.

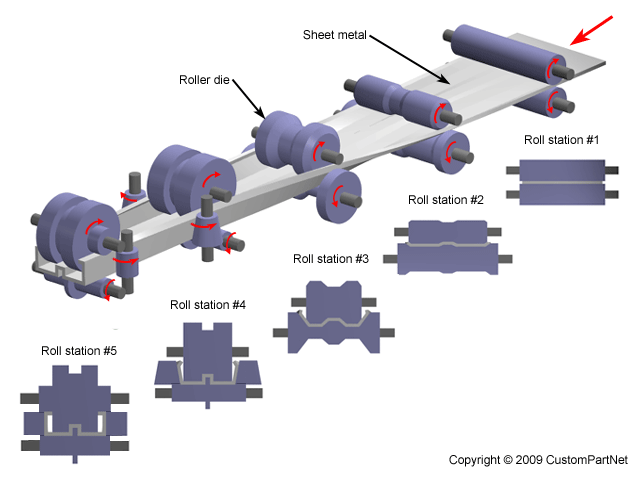

Rolling sheet metal to form cone.

Cones can be produced from a single piece of steel or in segments.

Cone bending on revolution machine tools r smart 6 709 plate roll presented by atakan nerminer for more info.

Steel plate rolling to make a cone.

If you want any other idea.

Here is a prototype model of sheet metal cone rolling machine.

Cut out your cone template from the sheet metal using your tin snips then file the edges smooth to avoid cutting yourself or someone else with the cone.

Steel plate is formed into cones primarily by either rolling the plate in a plate roll or forming the plate with radius dies in a press brake.

This is thick steel plate that was cut to size and then rolled here at jorgenson metal rolling forming to make a custom cone in 2 pieces.

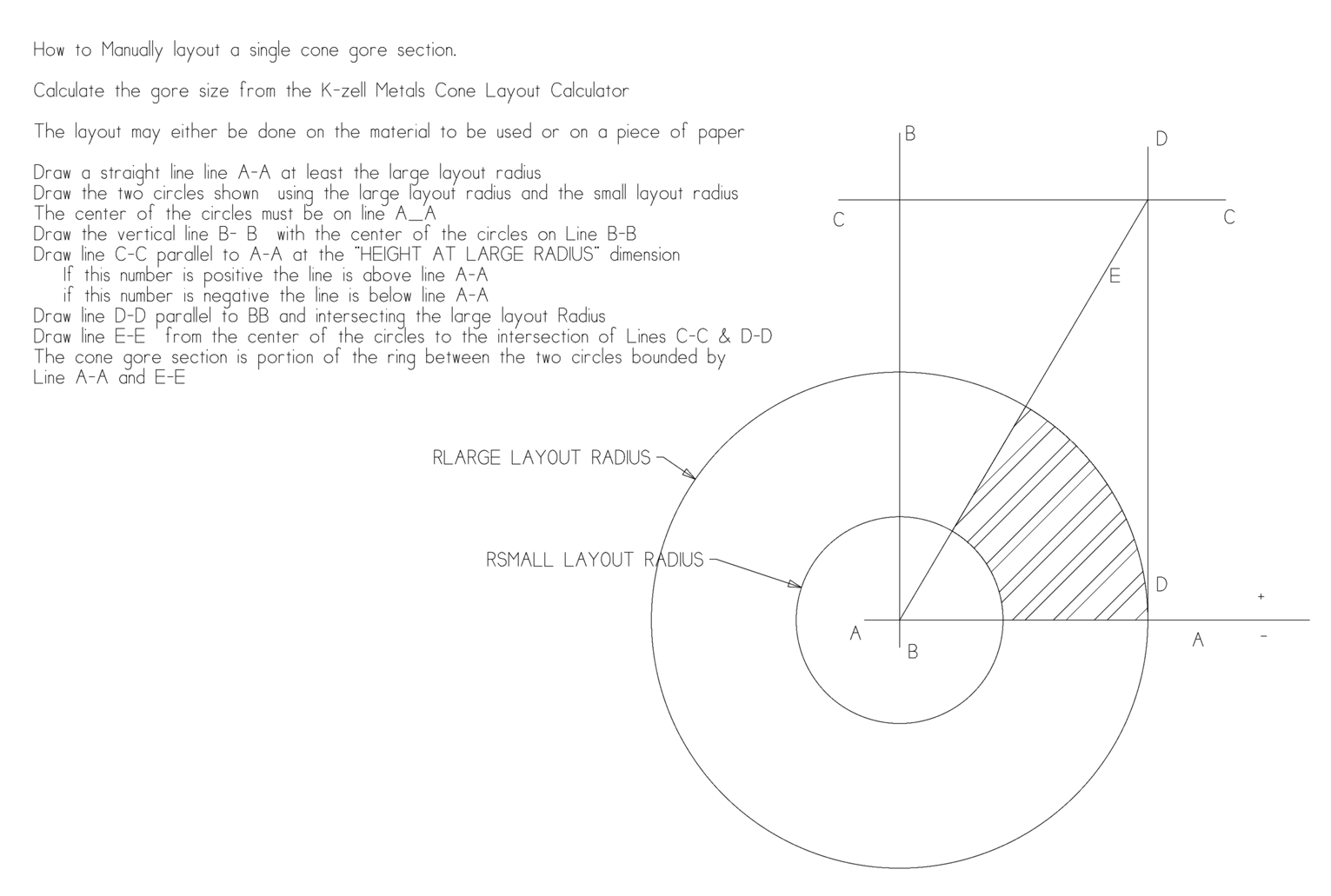

Sheet metal cone calculator.

View the cone instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections.

We can use up to 1 5 mm thick sheet on this prototype to make cone.

Plate and sheet metal rolling.

Some companies step brake lines into the metal but this usually leaves kinks at each place the plate is hit.